ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Corvette Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Oxygen Sensors found

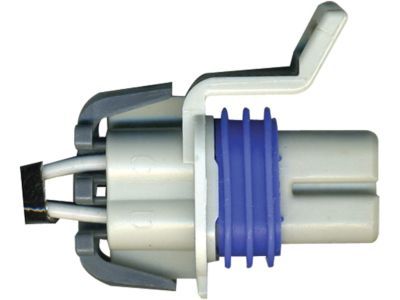

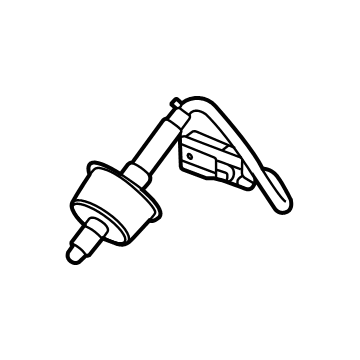

Chevrolet Corvette Oxygen Sensor Part Number: 19209807

$87.79 MSRP: $178.30You Save: $90.51 (51%)Ships in 1-2 Business Days

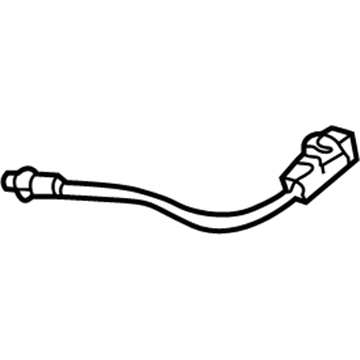

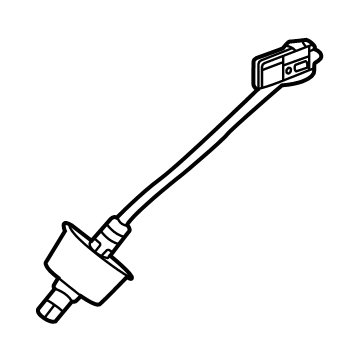

Chevrolet Corvette Oxygen Sensor Part Number: 19178930

$66.41 MSRP: $134.88You Save: $68.47 (51%)Ships in 1-2 Business Days

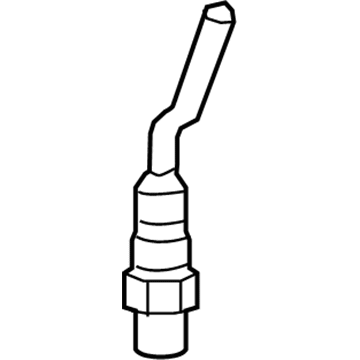

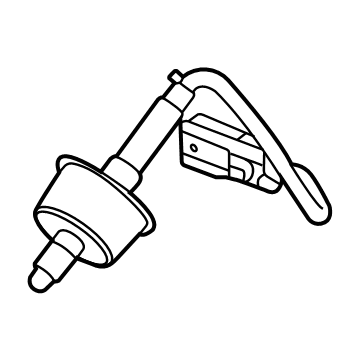

Chevrolet Corvette Oxygen Sensor Part Number: 12655678

$41.17 MSRP: $83.62You Save: $42.45 (51%)Ships in 1-2 Business Days

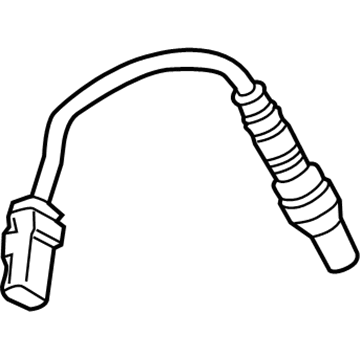

Chevrolet Corvette Oxygen Sensor Part Number: 12655677

$52.19 MSRP: $106.00You Save: $53.81 (51%)Ships in 1-2 Business Days

Chevrolet Corvette Oxygen Sensor Part Number: 12617332

$81.80 MSRP: $166.14You Save: $84.34 (51%)Ships in 1-2 Business Days

Chevrolet Corvette Oxygen Sensor Part Number: 12611165

$93.88 MSRP: $190.68You Save: $96.80 (51%)Ships in 1-2 Business Days

Chevrolet Corvette Oxygen Sensor Part Number: 12581966

$75.95 MSRP: $154.26You Save: $78.31 (51%)Ships in 1-2 Business DaysChevrolet Corvette Oxygen Sensor Part Number: 25176709

$39.65 MSRP: $97.46You Save: $57.81 (60%)Ships in 1-2 Business DaysChevrolet Corvette Oxygen Sensor Part Number: 10096129

$55.59 MSRP: $112.89You Save: $57.30 (51%)Ships in 1-2 Business DaysChevrolet Corvette Oxygen Sensor Part Number: 25176708

$55.59 MSRP: $112.89You Save: $57.30 (51%)Ships in 1-2 Business DaysChevrolet Corvette Oxygen Sensor Part Number: 19355313

$101.26 MSRP: $190.16You Save: $88.90 (47%)Ships in 1-2 Business DaysChevrolet Corvette Oxygen Sensor Part Number: 19355312

$85.11 MSRP: $172.86You Save: $87.75 (51%)Ships in 1-2 Business DaysChevrolet Corvette Oxygen Sensor Part Number: 12712497

$49.07 MSRP: $87.62You Save: $38.55 (44%)Ships in 1-3 Business DaysChevrolet Corvette Oxygen Sensor Part Number: 12703967

$67.13 MSRP: $119.88You Save: $52.75 (44%)Ships in 1-3 Business DaysChevrolet Corvette Oxygen Sensor Part Number: 12670254

$40.41 MSRP: $72.16You Save: $31.75 (44%)Chevrolet Corvette Oxygen Sensor Part Number: 12665161

$36.47 MSRP: $68.48You Save: $32.01 (47%)Ships in 1-2 Business DaysChevrolet Corvette Oxygen Sensor Part Number: 12683349

Chevrolet Corvette Oxygen Sensor Part Number: 19211437

$19.00 MSRP: $33.92You Save: $14.92 (44%)

Chevrolet Corvette Oxygen Sensor

Want to cut long-term maintenance and repair costs? Choose OEM Oxygen Sensor. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Corvette parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Corvette Oxygen Sensor includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

The Oxygen Sensor in Chevrolet Corvette automobiles assists in perfecting the air-fuel mixture as well as emission control because it sends information concerning the mixture ratio in the chamber directly to the ideal control panel. This sensor checks the quantity of oxygen contained in the exhaust emissions, through which the engine receives the right fuel mixtures for its highest performance. Zirconia and titania types of sensors have also been used in Corvette models and each has its own responsibilities in the management of fuel. This component is related to fuel emission since its failure is a common cause for increased fuel consumptions; the reasons are high mileage and inner contamination. It is advised to change oxygen sensor at the interval of every 75, 000- 100, 000 miles.

Chevrolet Corvette Oxygen Sensor Parts Questions & Experts Answers

- Q: How to service Bank 2 Sensor 1 of the oxygen sensor on Chevrolet Corvette?A:The first thing to do when it comes to servicing bank 2 sensor 1 of the Oxygen Sensor is to ensure that the pigtail and the connector of the heated Oxygen Sensor are intact, as the damage to the two will undermine its ability to function. Use care with the sensor, so no drops, and allow the in-line connector and the louvered end not to get contaminated; never use any cleaning solvents, or any attempts repair on the wiring, connector, and terminals have the ability to obstruct the need for external air reference and performance degradation. If the sensor is dropped or the pigtail wiring, terminals or connection is damaged, change the sensor. Do not forget that removal might be problematic in case the temperature is under 48 °c (120 °F), and if too much force is used, this might damage the Exhaust Manifold or the threads of the pipes. Initiate by lifting the vehicle and removing the ho2s electrical connector and then ordinate the heated Oxygen Sensor in an assertive manner. For installation, use the anti-seize compound p/n 5613695 on heated Oxygen Sensor threads to allow the removal of the Oxygen Sensor needed in the future; new or service sensors are usually supplied pre-coated. Mount the heated Oxygen Sensor and tighten it to 41 nm (30 lb ft), reconnect ho2s electrical connector, and lower the vehicle.