ChevyParts

My Garage

My Account

Cart

OEM Chevrolet Impala Brake Master Cylinder

- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

16 Brake Master Cylinders found

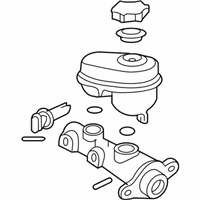

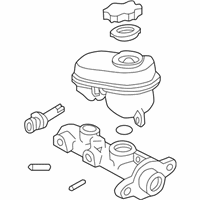

Chevrolet Impala Master Cylinder Part Number: 25509416

$91.40 MSRP: $163.22You Save: $71.82 (44%)Ships in 1-3 Business DaysChevrolet Impala Master Cylinder Part Number: 23176885

$130.85 MSRP: $253.96You Save: $123.11 (49%)Chevrolet Impala Master Cylinder Part Number: 22796285

$162.29 MSRP: $314.98You Save: $152.69 (49%)Ships in 1-2 Business Days

Chevrolet Impala Overhaul Kit Part Number: 18007935

Chevrolet Impala Master Cylinder Repair Kit Part Number: 25509843

Chevrolet Impala Master Cylinder Part Number: 18022002

Chevrolet Impala Master Cylinder Part Number: 18020914

Chevrolet Impala Master Cylinder Part Number: 19209261

Chevrolet Impala Master Cylinder Part Number: 19209260

Chevrolet Impala Master Cylinder Part Number: 19209247

Chevrolet Impala Master Cylinder Part Number: 19209185

Chevrolet Impala Master Cylinder Part Number: 18060781

Chevrolet Impala Master Cylinder Part Number: 18029971

Chevrolet Impala Master Cylinder Part Number: 18029966

Chevrolet Impala Master Cylinder Part Number: 18013426

Chevrolet Impala Master Cylinder Part Number: 15925739

Chevrolet Impala Brake Master Cylinder

Want to cut long-term maintenance and repair costs? Choose OEM Brake Master Cylinder. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Impala parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Impala Brake Master Cylinder includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

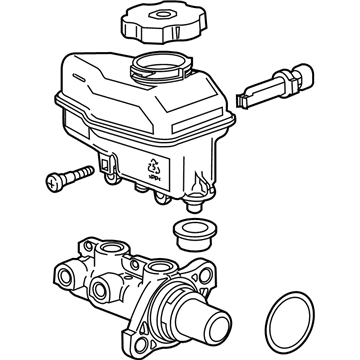

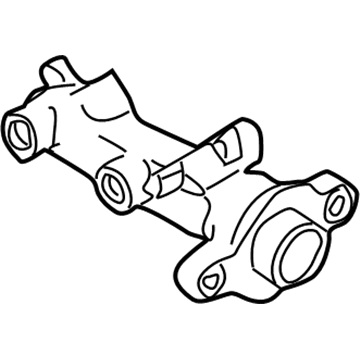

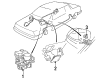

Brake Master Cylinder in Chevrolet Impala cars is an essential braking system unit of turning the force exerted by the foot into hydraulic pressure to compel slave cylinders. This system uses hydraulic fluid to transmits force from the master cylinder's piston to the slave cylinders; force and displacement are increased. Chevrolet Impala cars usually incorporate a dual circuit master cylinder with 2 pistons Operated whereby even if hydraulic pressure in either of the two circuits is lost, the continued pressure is enough for the car to stop. Master cylinder works operational calipers or drum brakes in order to generate some friction into the wheel in an endeavor to halt it and at the same times works for slave cylinder regarding clutch deactivation. In general, the Brake Master Cylinder in Chevrolet Impala automobiles plays a critical role of preventing the mishandling of hydraulic force and pressure which is very vital for the proper functioning of the brake and the clutch of the automobile.

Chevrolet Impala Brake Master Cylinder Parts and Q&A

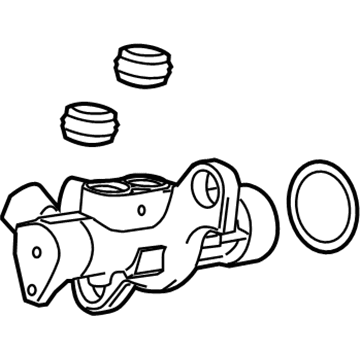

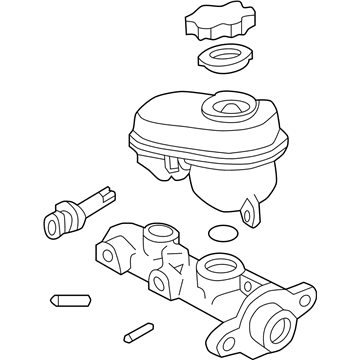

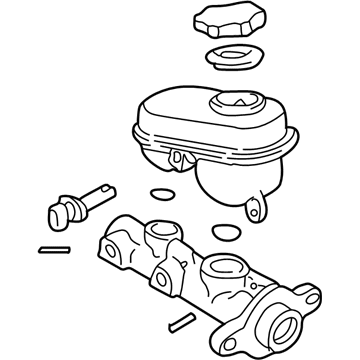

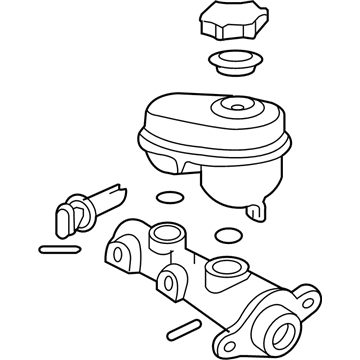

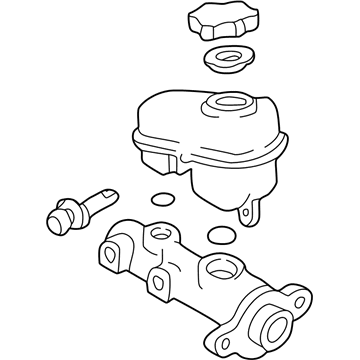

- Q: How to replace the brake master cylinder on Chevrolet Impala?A:Start Brake Master Cylinder replacement by disconnecting electrical cables from the brake sensor and brake lines. Install rubber caps to cover exposed brake pipe ends at the same time. Seal exposed brake pipes first and loosen the master cylinder mounting nuts before taking out the part from the vehicle. Empty the brake fluid entirely from the master cylinder reservoir system. Begin bleeding brake fluid from the master cylinder on a bench before you fit it to the vacuum Brake Booster and then screw on the master cylinder mounting nuts until they reach 33 n.m (24 lb ft) torque. Attach brake pipes to the master cylinder while tightening pipe fittings at the master cylinder to 18 n.m (13 lb ft). Connect the sensor power lead and start to bleed the brake system until the proper operation is achieved.

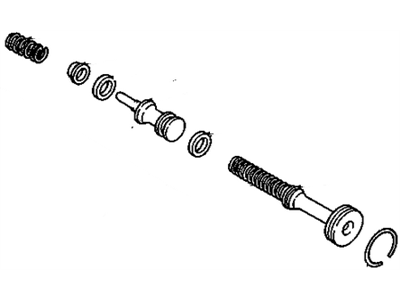

- Q: How to overhaul the brake master cylinder on Chevrolet Impala?A:The overhaul of the Brake Master Cylinder begins by uninstalling it from the vehicle while securing its mounting flange on a bench vise to access the primary Piston rear at the back. Before removing the reservoir cap and diaphragm check the surrounding area. Test for any cuts, cracks, nicks or deformation in both components and replace them if needed. A smooth round-ended tool should be used to depress the primary Piston until achieving primary Piston assembly removal together with Piston retainer removal. Low pressure, non-lubricated, filtered air should be introduced through the front outlet port while plugging all cylinder inlet ports and rear outlet port to remove the secondary Piston together with the primary and secondary seals and the return spring. The mechanic should remove the three components that compose the primary Piston assembly with its Piston retainer and seals. Use denatured alcohol to clean the master cylinder's interior and exterior along with its secondary Piston , return spring but avoid using abrasive materials. Evaluate each master cylinder component for damage from cracking, scoring, pitting or corrosion. Replace the master cylinder if either one of these defects appears. Use filtered non-lubricated air to dry all components before applying delco supreme ii® (GM P/N 12377967, Canadian P/N 992667) or equivalent dot-3 brake fluid from clean, sealed supply as lubrication for the master cylinder bore and secondary Piston and return spring as well as all overhaul components. Install the new primary seal and retainer with the new secondary seal onto the secondary Piston. Then position the lubricated return spring and secondary Piston assembly inside the cylinder bore before inserting the lubricated new primary Piston assembly . Use a smooth tool with a round end to compress the primary Piston before installing the Piston retainer. Depress the master cylinder reservoir back onto the vehicle by reinstalling its reservoir cap and diaphragm.