ChevyParts

My Garage

My Account

Cart

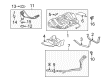

OEM Chevrolet Malibu Fuel Rail

Engine Fuel Rail- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

18 Fuel Rails found

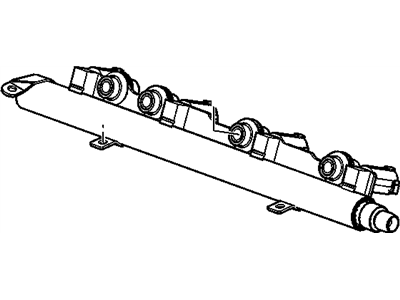

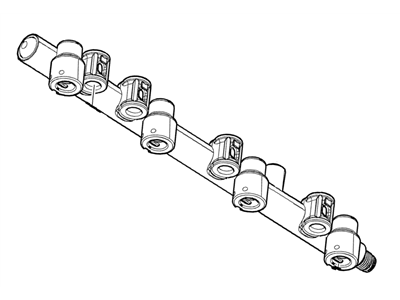

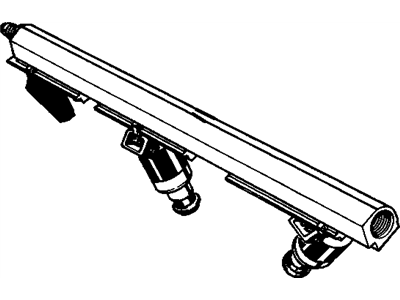

Chevrolet Malibu Fuel Rail Part Number: 12608366

$197.95 MSRP: $358.28You Save: $160.33 (45%)

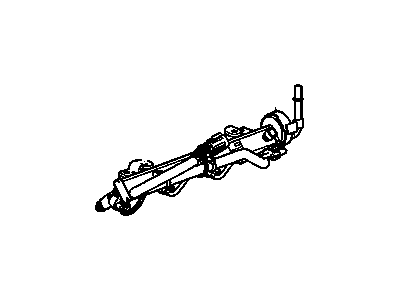

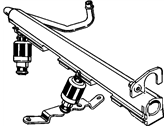

Chevrolet Malibu Fuel Rail, Green Line Part Number: 12602482

$167.94 MSRP: $341.10You Save: $173.16 (51%)Ships in 1-2 Business DaysChevrolet Malibu Fuel Rail Part Number: 17113318

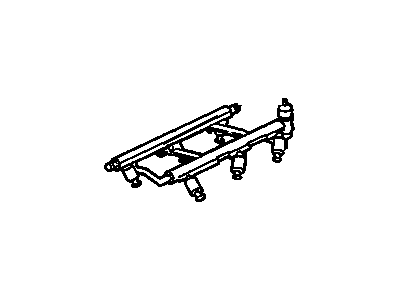

$37.16 MSRP: $319.94You Save: $282.78 (89%)Ships in 1-2 Business DaysChevrolet Malibu Fuel Rail Part Number: 17113256

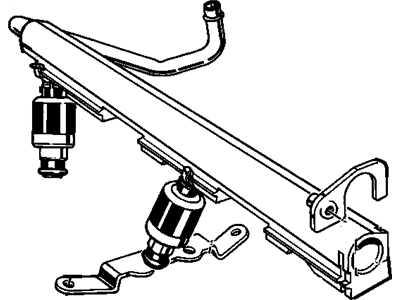

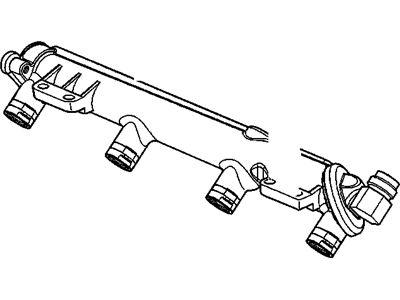

$113.11 MSRP: $229.18You Save: $116.07 (51%)Ships in 1-2 Business DaysChevrolet Malibu Fuel Rail Part Number: 55572748

$278.34 MSRP: $437.96You Save: $159.62 (37%)Ships in 1-3 Business DaysChevrolet Malibu Fuel Rail Part Number: 12684543

$149.87 MSRP: $235.79You Save: $85.92 (37%)Ships in 1-3 Business DaysChevrolet Malibu Fuel Rail Part Number: 17113608

$119.91 MSRP: $225.16You Save: $105.25 (47%)Ships in 1-2 Business DaysChevrolet Malibu Fuel Rail Part Number: 12662385

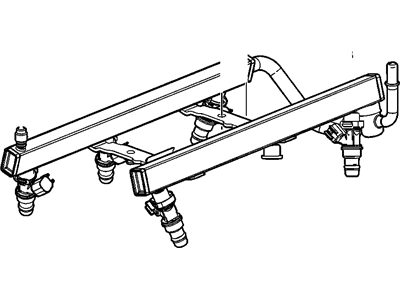

$366.08 MSRP: $743.54You Save: $377.46 (51%)Ships in 1-2 Business DaysChevrolet Malibu Fuel Rail Part Number: 12654644

$251.84 MSRP: $455.82You Save: $203.98 (45%)Ships in 1-3 Business DaysChevrolet Malibu Fuel Rail Part Number: 12627090

$251.84 MSRP: $455.82You Save: $203.98 (45%)Ships in 1-2 Business DaysChevrolet Malibu Fuel Rail Part Number: 12596571

$147.57 MSRP: $267.11You Save: $119.54 (45%)Ships in 1-2 Business DaysChevrolet Malibu Fuel Rail Part Number: 12584908

$226.88 MSRP: $460.82You Save: $233.94 (51%)Ships in 1-2 Business DaysChevrolet Malibu Fuel Rail Part Number: 17113579

Chevrolet Malibu Fuel Rail Part Number: 17113607

Chevrolet Malibu Fuel Rail Part Number: 17113268

Chevrolet Malibu Fuel Rail Part Number: 17113195

Chevrolet Malibu Fuel Rail Part Number: 12587074

Chevrolet Malibu Fuel Rail Part Number: 12586713

Chevrolet Malibu Fuel Rail

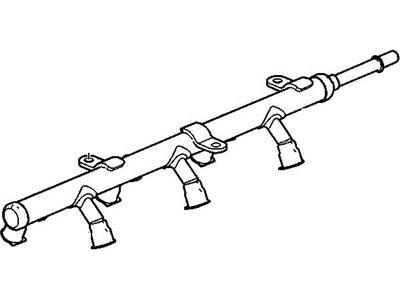

Want to cut long-term maintenance and repair costs? Choose OEM Fuel Rail. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet Malibu parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Malibu Fuel Rail includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Malibu Fuel Rail Parts Questions & Experts Answers

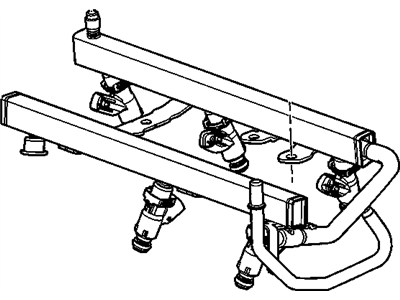

- Q: How to service the fuel rail on Chevrolet Malibu?A:The service of Fuel Rail starts with using proper procedures to reduce fuel system pressure. The task begins through the collection of necessary tools which should include the fuel line wrench (J43013). Disconnect both the Fuel Rail feed tube from the Fuel Rail as well as the fuel return tube from the Fuel Pressure Regulator after removing the upper Intake Manifold. You should remove the o-rings of both fuel feed pipe and fuel return pipe before disconnecting the main injector harness electrical connector. Press the lock release on the Fuel Injector connectors then depress the tab and properly remove the connector from the injector. Match the tasks through two steps in this order: start by taking off the Fuel Rail injector electrical harness then unplug the Coolant Temperature Sensor electrical connector. The procedure requires the removal of Fuel Rail retaining bolts before taking out the Fuel Rail assembly by discarding the injector o-ring seals but saving the o-ring back ups for future use. Prevent contamination between Fuel Rail installments by plugging inlet ports and outlet ports of the Fuel Rail. Mount the Fuel Rail assembly inside the Intake Manifold while tipping it to place the injectors correctly before tightening the Fuel Rail attaching bolts to 10 n.m (7 lb ft). Complete the Coolant Temperature Sensor electrical connection then mount the injector electrical harness onto the Fuel Rail followed by fitting all injector electrical connectors while sliding the locks fully into their position. Before finishing the procedure install new o-rings on both the fuel feed pipe and fuel return pipe while tightening the Fuel Rail engine nut to 17 n.m (13 lb ft). You need to complete fuel return pipe installation at the Fuel Pressure Regulator before tightening both the engine fuel return pipe nut to 17 n.m (13 lb ft) and placing back the upper Intake Manifold. In the last step reconnect the negative Battery Cable then check for fuel leakage by following the specific ignition on-off procedure.