ChevyParts

My Garage

My Account

Cart

OEM Buick Fuel Rail

Engine Fuel Rail- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

59 Fuel Rails found

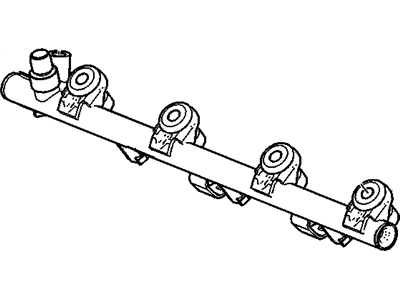

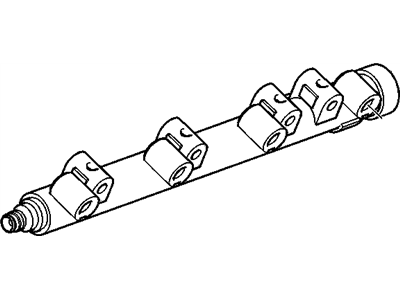

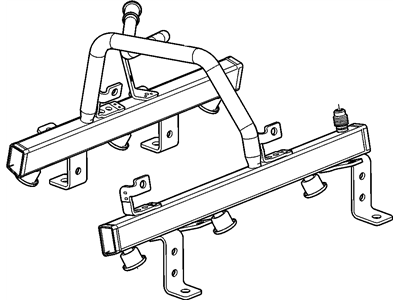

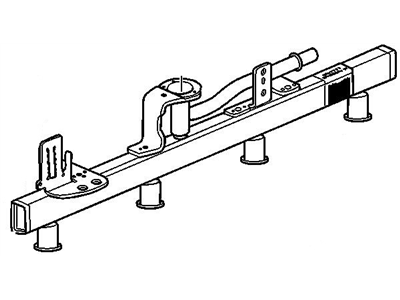

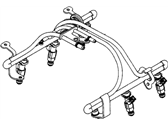

Buick Fuel Rail Part Number: 12701658

$183.80 MSRP: $329.68You Save: $145.88 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Rail, Fuel Injection

- Replaces: 12668188

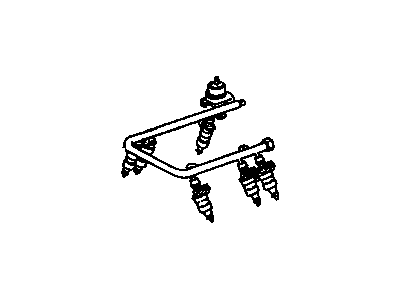

Buick Fuel Rail Part Number: 12615400

$415.96 MSRP: $752.86You Save: $336.90 (45%)Product Specifications- Other Name: Rail, Fuel Injection

- Replaces: 12589445, 12614848

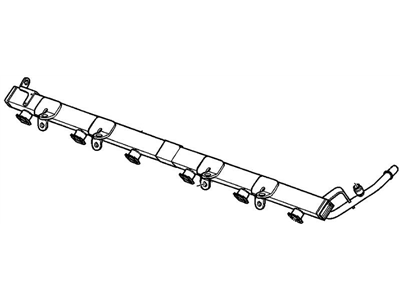

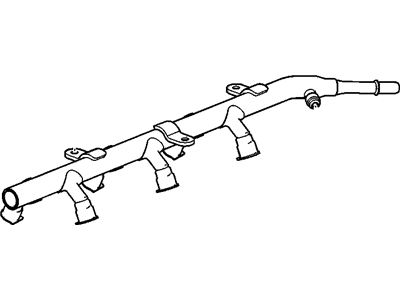

Buick Fuel Rail Part Number: 55515688

$230.87 MSRP: $414.12You Save: $183.25 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Rail Assembly-Direct Fuel Injection Fuel (W/ Fuel Injection Wiring H; Rail, Fuel Injection

- Replaced by: 25207704

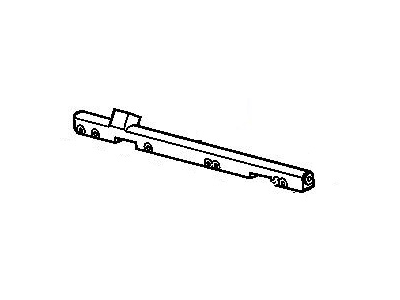

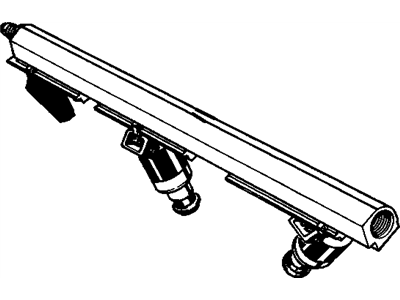

Buick Fuel Rail Part Number: 55486887

$114.60 MSRP: $180.33You Save: $65.73 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Rail Assembly-Direct Fuel Injection Fuel; Rail, Fuel Injection

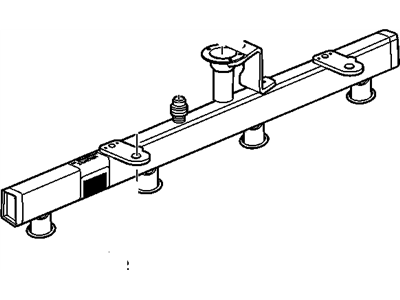

Buick Fuel Rail Part Number: 12706269

$125.35 MSRP: $197.22You Save: $71.87 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Rail, Fuel Injection

- Replaces: 12671079

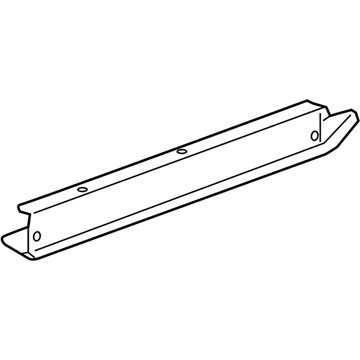

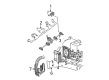

Buick Skid Plate, Passenger Side Part Number: 23241890

$89.99 MSRP: $140.83You Save: $50.84 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rail Assembly-Fuel Tank Skid; Fuel Tank Skid Plate

- Position: Passenger Side

- Replaced by: 84492429

Buick Skid Plate, Driver Side Part Number: 23241891

$35.62 MSRP: $55.74You Save: $20.12 (37%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Rail Assembly-Fuel Tank Skid; Fuel Tank Skid Plate

- Position: Driver Side

- Replaced by: 84492430

Buick Fuel Rail Part Number: 12579128

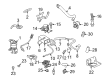

Product Specifications- Other Name: Rail Kit-Multiport Fuel Injection Fuel; Rail Kit, Fuel Injection

Buick Fuel Rail Part Number: 17113696

Product Specifications- Other Name: Rail, Fuel Injection

- Position: Driver Side

Buick Fuel Rail Part Number: 12617904

Product Specifications- Other Name: Rail, Fuel Injection; Rail Kit, Fuel Injection

- Replaces: 12575858

Buick Fuel Rail Part Number: 12592186

Product Specifications- Other Name: Rail; Rail, Fuel Injection

Buick Fuel Rail Part Number: 24500370

Product Specifications- Other Name: Rail, Luggage Carrier; Rail, Fuel Injection

Buick Fuel Rail Part Number: 12592187

Product Specifications- Other Name: Rail; Rail, Fuel Injection

Buick Fuel Rail Part Number: 17113251

Product Specifications- Other Name: Rail Kit; Rail Kit, Fuel Injection

Buick Fuel Rail Part Number: 25516337

Product Specifications- Other Name: Rail, Fuel Injection

Buick Fuel Rail Part Number: 12682763

Product Specifications- Other Name: Rail, Fuel Injection

Buick Fuel Rail Part Number: 12580913

Product Specifications- Other Name: Rail Kit, Fuel Injection; Rail, Fuel Injection

Buick Fuel Rail Part Number: 12580914

Product Specifications- Other Name: Rail Kit, Fuel Injection; Rail, Fuel Injection

Buick Fuel Rail Part Number: 12603212

Product Specifications- Other Name: Rail, Fuel Injection

Buick Fuel Rail Part Number: 17113607

Product Specifications- Other Name: Rail Kit, Fuel Injection; Rail, Fuel Injection

| Page 1 of 3 |Next >

1-20 of 59 Results

Buick Fuel Rail

Choose OEM Fuel Rail, you're making the optimal decision for superior quality and perfect performance. You can feel confident because each component goes through stringent quality checks. Every part is carefully built to comply with Buick's factory specifications. You'll enjoy a smooth, worry-free installation that fits just right. At ChevyPartsGiant.com, you'll find it easy to get top-quality OEM Buick Fuel Rail. You can shop at highly competitive prices and protect your budget. All our genuine Buick parts include a dependable manufacturer's warranty. You'll also appreciate our straightforward return policy and swift delivery services for extra convenience.

Buick Fuel Rail Parts and Q&A

- Q: How to replace the Fuel Injection Fuel Rail Assembly for Bank 1 (LLT) (3.6L) on Buick Enclave?A:The replacement of the fuel injection Fuel Rail assembly for bank 1 (LLT) (3.6L) requires the use of ch-48027 or without this tool to relieve fuel system pressure. You need to take away the fuel pipe shield and Intake Manifold as well as the high-pressure fuel pipe for disposal. Remove the Fuel Rail crossover pipe first while discarding it and extract the foam insulator covering the fuel rails. Disconnect the electrical connector of the Fuel Pressure Sensor and sever the wire harness tie straps. Sever the Fuel Pressure Sensor connection wires followed by removal of the Fuel Rail bolts together with the Fuel Pressure Sensor. Discard both clevis-type clamps used for Fuel Injector holding as direct fuel injectors require rebuilding after leaving their respective rail and cylinder positions. Proper Fuel Injector rebuild becomes necessary before reinstalling the Fuel Rail. The direct fuel injectors should be installed inside cylinder heads before securing them utilizing new hold down clamps. Position a new Fuel Rail correctly after lubricating its Fuel Injector cups with gm p/n 12345610 (Canadian P/N 9931930) or equivalent engine oil and begin bolting it from the outside then the inside while maintaining light hand torque. The mechanics should torque bank 1 Fuel Rail bolts initially to 12 nm (106 lb in) during the initial stage and reach a final torque setting of 23 nm (17 lb ft). The new installation of a Fuel Rail crossover pipe must be accompanied by a high-pressure fuel pipe as well as a high-pressure fuel sensor. The wiring harness electrical connector needs to connect to each injector and rail and pressure sensor. Start the ignition when the engine is off for a period of two seconds then shut it off for ten seconds while inspecting for fuel leakage before restarting the ignition. The repair process concludes by reattaching the foam insulator together with the Intake Manifold and fuel pipe shield and low side fuel pressure service port cap and fuel tank cap.

- Q: How to replace the fuel rail assembly on Buick Regal?A:The first step before changing the Fuel Rail assembly requires you to eliminate fuel pressure from your system before cleaning both the Fuel Rail assembly and its connections. First disconnect the fuel feed pipe along with the fuel return pipe from the Fuel Rail followed by removal of the vacuum line from the Fuel Pressure Regulator. First disconnect the ignition coil wires from their positions on top of the supercharger near the coil retainer clips and then disconnect the generator brace followed by the bypass valve actuator. You should disconnect the wires for the fuel injectors while also taking away the clips that connect the harness to the Fuel Rail front and rear. The left engine mount strut requires removal of its bolt and nut while the wiring harness must be displaced from the left engine mount strut bracket before eliminating the Fuel Rail hold-down nuts and stud. Use gentle force to take out the Fuel Rail applying the same pressure throughout the complete length. To install the Fuel Rail assembly place it on the Intake Manifold while hand-seating the fuel injectors before lightly applying clean engine oil to Fuel Injector o-rings followed by o-ring replacement on all serviced parts. The technician should install the Fuel Rail hold-down nuts first before torquing them to 10 n.m (89 lb in) and then install the Fuel Rail hold-down stud at 25 n.m (18 lb ft). Position the engine mount strut wiring harness followed by attaching the left engine mount strut bolt then tighten the nut to 48 n.m (35 lb ft). The Fuel Injector electrical harness needs its clips to be put back together while the electrical connectors are connected to the fuel injectors and the bypass valve actuator must be installed. After reinstalling the rear generator bracket and generator the next steps are to trace the ignition coil wires into retainer clips and to link the Fuel Pressure Regulator to its vacuum line and to bring the fuel feed and return pipes to the Fuel Rail. The negative Battery Cable installation should be completed along with leak inspection using ignition on-off cycles before installing the Fuel Injector sight shield.