ChevyParts

My Garage

My Account

Cart

OEM Cadillac Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

592 Shock Absorbers found

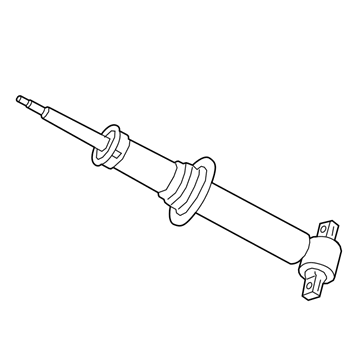

Cadillac Strut Part Number: 84844872

$76.37 MSRP: $209.89You Save: $133.52 (64%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shock Absorber

- Position: Rear

- Replaced by: 84844865

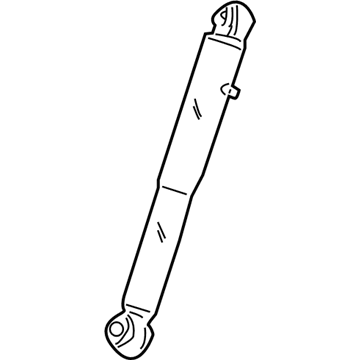

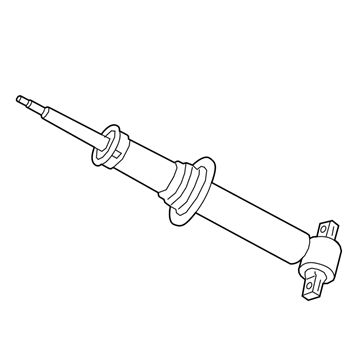

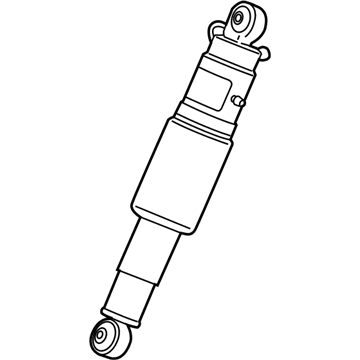

Cadillac Shock Absorber, Rear Part Number: 12476113

$295.53 MSRP: $578.62You Save: $283.09 (49%)Product Specifications- Other Name: Absorber Kit, Rear Shock; Shock; Absorber Kit, Front And Rear Suspension

- Position: Rear

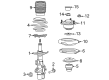

Cadillac Shock Absorber Part Number: 23183850

$176.18 MSRP: $341.94You Save: $165.76 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Suspension Strut and Shock Absorber Assembly Kit; Suspension Strut Assembly Kit; Strut Shock Kit; Complete Strut; Shock; Absorber, Front And Rear Suspension

- Position: Rear

- Replaces: 23452955

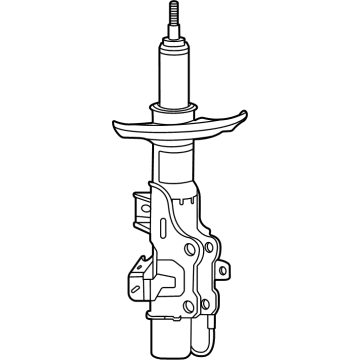

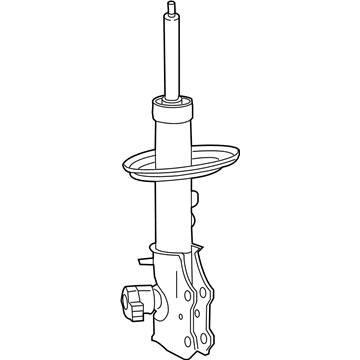

Cadillac Strut Part Number: 20765196

$97.53 MSRP: $189.32You Save: $91.79 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber, Shock; Shock Absorber; Absorber, Front And Rear Suspension

- Position: Front

- Replaces: 25871207

Cadillac Strut Part Number: 23425611

$89.89 MSRP: $160.52You Save: $70.63 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Absorber, Shock; Suspension Strut and Shock Assembly Kit; Complete Strut Set.

- Position: Front

Cadillac Shock Absorber Part Number: 22811843

$30.46 MSRP: $106.44You Save: $75.98 (72%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Suspension Strut and Shock Absorber Assembly Kit; Air to Coil Spring Conversion; Complete Strut Kit.; Shock; Absorber, Front And Rear Suspension

- Position: Rear

Cadillac Strut Part Number: 23179308

$123.29 MSRP: $221.14You Save: $97.85 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber, Shock; Suspension Strut and Shock Assembly Kit; Complete Strut Set.; Absorber, Front And Rear Suspension; Shock

- Position: Front

- Replaced by: 85669604

- Replaces: 23124590, 23183876, 23179303, 23183864, 23124594, 23124589, 23172263

Cadillac Strut Part Number: 84844868

$113.62 MSRP: $203.80You Save: $90.18 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Shock Absorber; Absorber, Front And Rear Suspension

- Position: Rear

Cadillac Strut Part Number: 23275423

$44.40 MSRP: $122.05You Save: $77.65 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber, Shock; Suspension Strut and Shock Assembly Kit; Complete Strut Set.; Absorber, Front And Rear Suspension; Shock

- Position: Front

Cadillac Strut Part Number: 20958799

$66.35 MSRP: $182.37You Save: $116.02 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber, Shock; Suspension Strut and Shock Assembly Kit; Air to Coil Spring Conversion; Complete Strut Kit.; Absorber, Front And Rear Suspension

- Position: Front

- Replaces: 20833673, 20833674

Cadillac Strut Part Number: 23156082

$75.48 MSRP: $207.50You Save: $132.02 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber, Shock; Suspension Strut and Shock Assembly Kit; Complete Strut Set.; Absorber, Front And Rear Suspension; Shock

- Position: Front

Cadillac Shock Absorber Part Number: 84844809

$112.93 MSRP: $221.09You Save: $108.16 (49%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Absorber, Shock; Strut; Absorber, Front And Rear Suspension

- Position: Front

- Replaced by: 84844802

Cadillac Shock Absorber Part Number: 84082040

$48.60 MSRP: $133.59You Save: $84.99 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Suspension Strut and Shock Absorber Assembly Kit; Suspension Strut Assembly Kit; Strut Shock Kit; Complete Strut; Shock; Absorber, Front And Rear Suspension

- Position: Rear

- Replaced by: 85669828

Cadillac Shock, Rear Part Number: 12477517

$376.72 MSRP: $731.15You Save: $354.43 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber Kit, Rear Shock; Shock Absorber; Absorber Kit, Front And Rear Suspension

- Position: Rear

Cadillac Shock Absorber Part Number: 84458386

$111.41 MSRP: $209.22You Save: $97.81 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber, Shock; Suspension Shock Absorber; Strut; Absorber, Front And Rear Suspension; Shock

- Position: Front

Cadillac Strut, Passenger Side Part Number: 84810468

$95.49 MSRP: $170.53You Save: $75.04 (44%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Strut, Front And Rear Suspension; Shock Absorber

- Position: Passenger Side

Cadillac Strut Part Number: 84043195

$91.38 MSRP: $177.37You Save: $85.99 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber, Shock; Suspension Strut and Shock Assembly Kit; Complete Strut Set.; Absorber, Front And Rear Suspension; Shock

- Position: Front

- Replaced by: 85669681

Cadillac Shock Absorber Part Number: 84082042

$63.79 MSRP: $124.89You Save: $61.10 (49%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Suspension Strut and Shock Absorber Assembly Kit; Complete Strut and Shock Absorber Set.; Shock; Absorber, Front And Rear Suspension

- Position: Rear

- Replaced by: 85669832

Cadillac Strut, Driver Side Part Number: 84643236

$258.85 MSRP: $464.29You Save: $205.44 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Strut, Front And Rear Suspension; Shock Absorber

- Position: Driver Side

Cadillac Shock Absorber Part Number: 84171354

$72.52 MSRP: $199.30You Save: $126.78 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Absorber, Shock; Suspension Shock Absorber; Strut; Absorber, Front And Rear Suspension; Shock

- Position: Front

- Replaced by: 85559796

| Page 1 of 30 |Next >

1-20 of 592 Results

Cadillac Shock Absorber

Want to cut long-term maintenance and repair costs? Choose OEM Shock Absorber. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Cadillac parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Cadillac Shock Absorber includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Cadillac Shock Absorber Parts and Q&A

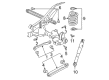

- Q: How to replace the shock absorber in the rear suspension on Cadillac CTS?A:Starting the shock absorber replacement for the rear suspension requires users to remove the rear seat back followed by relocation of the sound insulator away from the shock tower. The next step requires you to eliminate the top shock mounting bolts followed by lifting and supporting the vehicle. The shock absorber can be taken out of the vehicle after removing the lower shock mounting bolt. The first step for installation requires the shock to be placed back into the vehicle with attention to the Fastener Notice requirements. Set the lower shock mounting bolt in position before tightening it to 150 N.m (111 lb ft). The shock must lead into the body structure as you lower the vehicle until you tighten the upper shock mounting nuts to 25 N.m (18 lb ft). The finishing step is to place the sound insulator around the shock tower before you put the rear seat back.

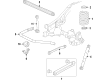

- Q: How to replace a shock absorber on Cadillac Escalade?A:Vehicle elevation and support are necessary before jacking the lower Control Arm for Shock Absorber replacement. You can remove the electronic suspension control (ESC) link rod from its sensor when present after rotating the lock tabs counterclockwise first to unlock the connector. Pull up the connector to disconnect it properly. Starting from the tennon end apply a wrench to prevent loosening before removing the nut as you take off the upper insulator and maintain the plastic pilot ring in place. Separate the Shock Absorber mounting bolt at the lower Control Arm which applies to 15 series and 25/35 series units and extract the Shock Absorber. The installation process begins by feeding the Shock Absorber stem into the shock bracket on the frame while positioning it identical to the lower Control Arm mounting holes of both 15 and 25/35 series. Connect the Shock Absorber bolt to the lower Control Arm before installing its nut and tighten it to 80 n.m (59 lb ft). Secure the upper insulator onto the shock mounting bracket by placing it on the frame using the plastic pilot ring for placement and avoid tightening the nut on the tennon end. The esc link rod should be reconnected after which safety stands can be removed and the vehicle can be lowered. The tennon end requires torqueing with a wrench until it reaches 20 n.m (15 lb ft) before safe disposal of the Shock Absorber.