ChevyParts

My Garage

My Account

Cart

OEM GMC Savana 3500 Crankshaft Position Sensor

Engine Crankshaft Position Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Crankshaft Position Sensors found

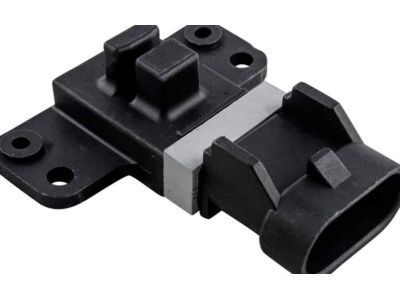

GMC Savana 3500 Crankshaft Position Sensor Part Number: 12596851

$69.25 MSRP: $140.64You Save: $71.39 (51%)

GMC Savana 3500 Crankshaft Position Sensor Part Number: 97365037

$75.79 MSRP: $153.94You Save: $78.15 (51%)Ships in 1-2 Business Days

GMC Savana 3500 Camshaft Position Sensor Part Number: 19417445

$66.52 MSRP: $124.92You Save: $58.40 (47%)Ships in 1 Business Day

GMC Savana 3500 Crankshaft Position Sensor Part Number: 12669636

$28.91 MSRP: $54.30You Save: $25.39 (47%)Ships in 1-3 Business Days

GMC Savana 3500 Crankshaft Position Sensor Part Number: 12560228

$58.99 MSRP: $119.82You Save: $60.83 (51%)GMC Savana 3500 Crankshaft Position Sensor Part Number: 55593759

$31.31 MSRP: $58.80You Save: $27.49 (47%)Ships in 1-2 Business DaysGMC Savana 3500 Crankshaft Position Sensor Part Number: 12575172

$80.04 MSRP: $144.85You Save: $64.81 (45%)GMC Savana 3500 Crankshaft Position Sensor Part Number: 12672641

$36.91 MSRP: $74.98You Save: $38.07 (51%)Ships in 1-2 Business Days

GMC Savana 3500 Crankshaft Position Sensor Part Number: 12557046

GMC Savana 3500 Crankshaft Position Sensor Part Number: 12703627

$60.13 MSRP: $107.38You Save: $47.25 (44%)

GMC Savana 3500 Crankshaft Position Sensor

Want to cut long-term maintenance and repair costs? Choose OEM Crankshaft Position Sensor. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC Savana 3500 parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Savana 3500 Crankshaft Position Sensor includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Savana 3500 Crankshaft Position Sensor Parts Questions & Experts Answers

- Q: How to service and repair the Crankshaft Position Sensor on GMC Savana 3500?A:To service and repair Crankshaft Position Sensor, start by using a scan tool and looking up the powertrain control module for dtcs and if any dtcs except p1336 are found, refer to the dtc list for additional information. Choose the crank shaft position variation learn procedure from the scan tool and note the fuel interruption for the concerned engine. Follow the scan tool's instructions: block the drive wheels, engage the parking brake on the vehicle, cycle the ignition from off to on holding the Brake Pedal, start and idle the engine, turn off the a/c, and turn the vehicle transmission to park (A/T) or to neutral (M/T). The scan tool will check some of the signals of the components to ensure that all the conditions are fulfilled, like ckp sensor activity, cmp sensor activity, and engine coolant temperature; ride the engine until such time as the correct level of coolant temperature is achieved should it be low. Begin the crankshaft position system variation learn procedure with the scan tool while during this process, being quick to release the throttle if the engine begins to decelerate allowing the engine control back into the operator's hands. Slowly increase the engine speed to observed rpm and let off the throttle when the fuel cut-off is achieved. The scan tool will indicate "learn status: learned this ignition"; learned this ignition"; and if message is not displayed, and no other dtcs are stored, check for engine symptoms, and if dtc (s) present, refer to dtc list. At last, turn off the ignition for 30 seconds after successfully completing the learn procedure.