ChevyParts

My Garage

My Account

Cart

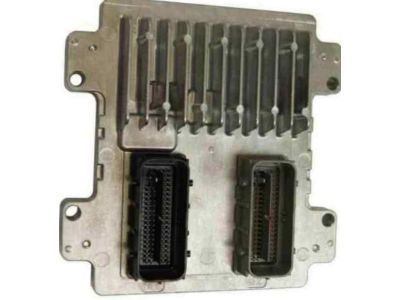

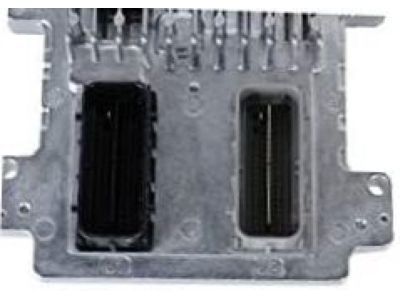

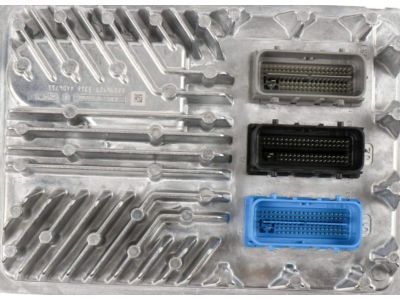

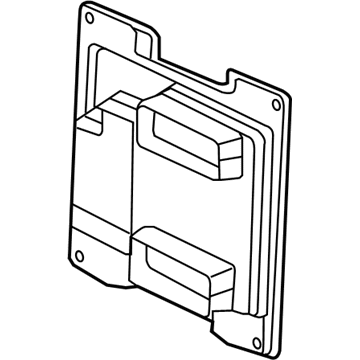

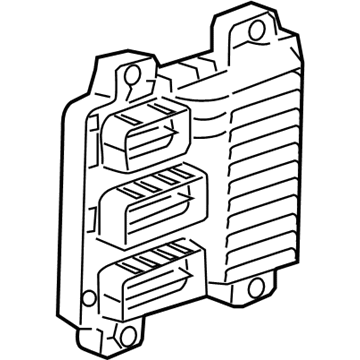

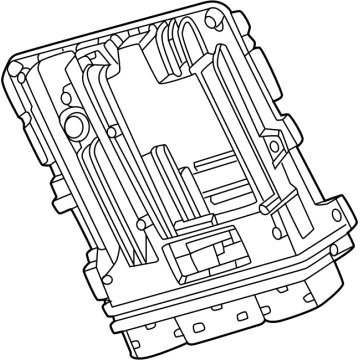

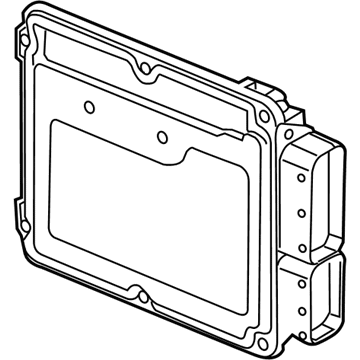

OEM Chevrolet Engine Control Module

Engine Control Computer- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

258 Engine Control Modules found

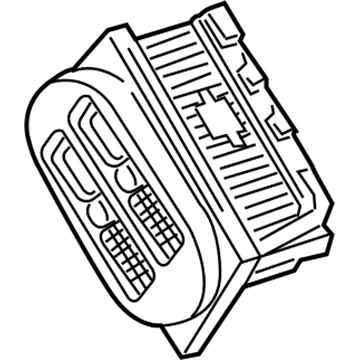

Chevrolet ECM Part Number: 12635043

$213.69 MSRP: $434.02You Save: $220.33 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module, Emission Control System; Engine Control Module

Chevrolet ECM Part Number: 12692068

$279.58 MSRP: $566.80You Save: $287.22 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module Assembly-Engine Control (W/2ND Mpu) E92 Service ECM, 5 Byt; Engine Control Module

- Replaced by: 12704476

Chevrolet ECM Part Number: 12623327

$272.19 MSRP: $552.85You Save: $280.66 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module, Emission Control System; Engine Control Module

- Replaces: 12614423

Chevrolet ECM Part Number: 12692067

$278.29 MSRP: $564.16You Save: $285.87 (51%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Module Assembly-Engine Control (W/2ND Mpu) E92 Service ECM 2-Byte; Engine Control Module

- Replaced by: 12704477

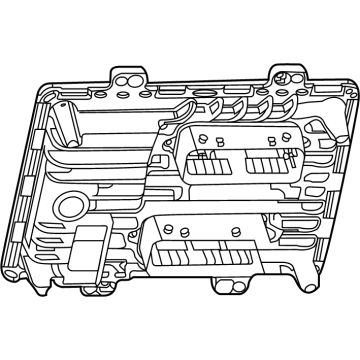

Chevrolet PCM Part Number: 19210070

$316.50 MSRP: $592.06You Save: $275.56 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module Assembly, Powertrain Control; Engine Control Module; ECM; Module, Emission Control System

Chevrolet Control Module Part Number: 16197409

$36.37 MSRP: $193.38You Save: $157.01 (82%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module Assembly, Engine Control (Remanufactured); Module, Emission Control System

Chevrolet ECM Part Number: 12721353

$185.01 MSRP: $331.86You Save: $146.85 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Module Assembly-Engine Control (W/ 2ND Mpu) & (W/O C; Module, Emission Control System

- Replaces: 55512265

Chevrolet ECM Part Number: 12725415

$259.04 MSRP: $526.15You Save: $267.11 (51%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Module Assembly-Engine Control (W/O Calibration); Module, Emission Control System

- Replaces: 12718010

Chevrolet ECM Part Number: 12686366

$294.03 MSRP: $552.16You Save: $258.13 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module, Emission Control System; Engine Control Module

- Replaces: 12676940

Chevrolet PCM Part Number: 12667002

$248.14 MSRP: $504.00You Save: $255.86 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module, Emission Control System; Engine Control Module; ECM

Chevrolet PCM Part Number: 12209614

$322.30 MSRP: $583.37You Save: $261.07 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module, Emission Control System; Engine Control Module; ECM

- Replaced by: 19433893

Chevrolet ECM Part Number: 12721177

$405.64 MSRP: $727.61You Save: $321.97 (45%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Module, Emission Control System

Chevrolet ECM Part Number: 12693091

$127.06 MSRP: $258.06You Save: $131.00 (51%)Product Specifications- Other Name: Module Assembly-Engine Control (W/2ND Mpu) E84B Service No Start; Engine Control Module; Module, Emission Control System

Chevrolet ECM Part Number: 12646983

$527.30 MSRP: $990.24You Save: $462.94 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module Assembly, Engine Control (W/2ND Mpu); Engine Control Module; Module, Emission Control System

Chevrolet ECM Part Number: 12719704

$190.48 MSRP: $386.88You Save: $196.40 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module Assembly-Engine Control (W/O Calibration); Module, Emission Control System

- Replaces: 12711353

Chevrolet PCM Part Number: 19210069

$339.79 MSRP: $618.94You Save: $279.15 (46%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module Assembly, Powertrain Control; Engine Control Module; ECM; Module, Emission Control System

Chevrolet PCM Part Number: 16228016

$389.37 MSRP: $702.35You Save: $312.98 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Module, Emission Control System; Engine Control Module; ECM

- Replaced by: 19433896

Chevrolet Control Module Part Number: 9374997

Product Specifications- Other Name: Module Assembly, Powertrain Control (Remanufacture) Requires Reprogramming; Engine Control Module; ECM; Module, Emission Control System

Chevrolet ECM Part Number: 12723949

$188.07 MSRP: $337.34You Save: $149.27 (45%)Product Specifications- Other Name: Module Assembly-Engine Control (W/O Calibration); Module, Emission Control System

- Replaces: 24001956

Chevrolet ECM Part Number: 12721348

$209.16 MSRP: $375.19You Save: $166.03 (45%)Product Specifications- Other Name: Module Assembly-Engine Control (W/2ND Mpu); Module, Emission Control System

- Replaces: 24000461, 55502052

| Page 1 of 13 |Next >

1-20 of 258 Results

Chevrolet Engine Control Module

Want to cut long-term maintenance and repair costs? Choose OEM Engine Control Module. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine Chevrolet parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM Chevrolet Engine Control Module includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

Chevrolet Engine Control Module Parts Questions & Experts Answers

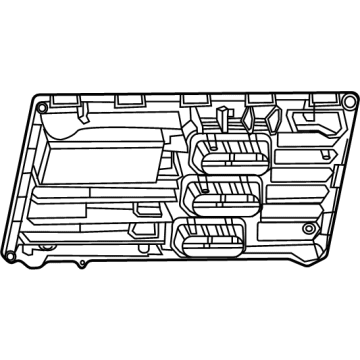

- Q: What does the service of the engine control module (ECM) typically involve on Chevrolet Colorado?A:Ecm service requires either a replacement of the ecm or eeprom programming services. Check that the installed ecm part matches the original requirement before any replacements. The new service ecm should be installed after you confirm the failed ecm. Vehicle owners must perform a cpps learn procedure both when changing the ecm or reprogramming it as well as when they replace or install the clutch pedal position sensor (CPPS) to prevent accidents and damage to the car when the Starter engages the gear. All operations of control module connectors and power connections need to be done under an off state ignition setting to stop damages occurring inside the control module. When working on the control module allow only the case material to contact battery voltage and refrain from touching both pins and soldered components on the circuit board to resist electrostatic damage. Check that all surfaces on control module connectors are clean from debris before testing the gaskets of connectors to stop contaminants from entering the system. Programming the replacement control module is required with necessary information about engine oil life but if programming is not performed the default setting will trigger a complete oil change needed at 5000 km (3,000 mi) from the last change. Through a scan tool check the ecm for its engine oil life percentage before removing the connectors from the ecm while implementing electrostatic discharge avoidance. The first step to remove the ecm requires disconnecting screws holding the mounting brackets. The installation process begins by inserting the ecm into its mounting bracket where tabs should completely fit before connecting ecm harness connectors to the ecm body. A new ecm requires programming after its installation. Perform the clutch pedal position sensor learn procedure when you have a manual transmission vehicle.

- Q: How to program the Engine Control Module on Chevrolet Malibu?A:The programming of Engine Control Modules should start by gathering the vehicle's VIN. The Techline(R) terminal allows programmers to access Service Programming followed by choosing Tech 2(R) and Reprogram ECU then specifying Off-Board Programming Adapter as the ECU location. The correct harness connector from the Off-Board Programming Adapter kit needs to connect the control module and Off-Board Programming Adapter with Tech 2(R). Access the Service Programming Request Information feature from the Tech 2(R) device to establish connection with the control module before getting the access code followed by exiting the feature. Connect the Tech 2(R) to the Techline(R) terminal while turning it ON after removing it from the Off-Board Programming Adapter. The user must input their vehicle's VIN into the Techline(R) terminal after which the terminal will show the necessary database connection message. The first step is to choose the correct programming type then access the appropriate calibration file while making sure all connections remain fastened. After verifying the calibration summary on the Techline(R) terminal it begins an automatic file transfer to the Tech 2(R). Close the Tech 2(R) system after completion of the download process and disconnect it from the Techline(R) terminal before connecting it to the Off-Board Programming Adapter. Select Service Programming on the Tech 2(R). The programming process should be completed while keeping the Off-Board Programming Adapter powered up because security connections must remain intact and Techline(R) operating software needs to be updated before starting another control module reprogramming attempt. A failed reprogramming process requires replacement of the control module. To conclude select Program from the Tech 2(R) then disable Service Programming and complete the download before turning OFF the Off-Board Programming Adapter.

- Q: What is the function of the Engine Control Module in programming control modules on Chevrolet S10?A:The service programming system (SPS) allows technicians to program control modules through the data link connector (DLC) by utilizing the same serial data circuit that scan tools use for diagnostic trouble code (DTC) retrieval along with data reading. Control modules incorporate electrically erasable programmable read only memory (EEPROM) that saves information like vehicle identification number (VIN) along with crankshaft variation learned position and control module security information and software/calibrations identification numbers yet flash read only memory possesses higher storage capacity since programming blanks it entirely to insert new content. The programming procedures consist of remote and pass thru options with (Tech 2) devices alongside off-board remote and off-board pass thru capabilities and (OBPA). Before programming a control module must start only during cases where module replacement or new software release is necessary and when checking that system voltage falls between 12 to 16 volts and charging systems function properly and no battery charger is attached. First disable battery-loading systems then put the Ignition Switch correctly and double-check all tool connections remain secure. Tool harness disturbance should be avoided throughout programming steps to prevent both failures and equipment damage. After programming, the powertrain may operate differently, requiring the control module to re-learn values such as fuel trim correction, idle air control (IAC) learned position, and automatic transmission shift adapts, while additional service procedures may be necessary if a control module is replaced, including the crankshaft variation learn procedure, engine oil life reset procedure, idle learn procedure, inspection/maintenance complete system set procedure, vehicle theft deterrent password learn procedure, and throttle position (TP) sensor learn procedure.

Related Chevrolet Parts

Browse Chevrolet Engine Control Module by Models

Nova S10 Colorado C10 Tahoe Cruze Malibu Camaro Equinox Impala SS SSR Avalanche Silverado 1500 Silverado 2500 HD Caprice Classic Cobalt Suburban Traverse Blazer HHR Sonic Tracker Volt El Camino K10 Spark Trax Trailblazer Astro Cavalier Corvette C20 Aveo Beretta C1500 C2500 C30 C3500 Celebrity Chevette City Express Corsica Express 1500 Express 2500 Express 3500 G10 G20 G30 K1500 K20 K2500 K30 K3500 K5 Blazer Lumina Metro Monte Carlo P30 Prizm S10 Blazer Silverado 2500 Sprint Uplander Venture Lumina APV Silverado 3500 Suburban 1500 Trailblazer EXT Avalanche 1500 Avalanche 2500 Aveo5 C10 Suburban C1500 Suburban C20 Suburban C2500 Suburban Captiva Sport Cruze Limited Impala Limited K10 Suburban K1500 Suburban K20 Suburban K2500 Suburban Malibu Limited P20 R10 R10 Suburban R1500 Suburban R20 R20 Suburban R2500 R2500 Suburban R30 R3500 Silverado 1500 Classic Silverado 1500 HD Silverado 1500 LD Silverado 1500 LTD Silverado 2500 HD Classic Silverado 3500 Classic Silverado 3500 HD Spark EV Spectrum Suburban 2500 Suburban 3500 HD V10 V10 Suburban V1500 Suburban V20 V20 Suburban V2500 Suburban V30 V3500