ChevyParts

My Garage

My Account

Cart

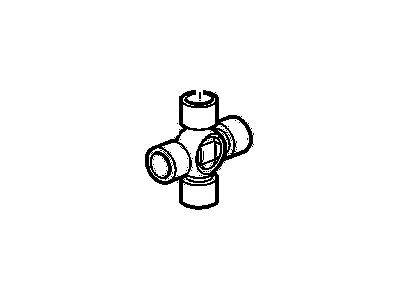

OEM GMC Universal Joint

U-Joint- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

19 Universal Joints found

GMC Universal Joints Part Number: 23104840

$36.45 MSRP: $88.98You Save: $52.53 (60%)Product Specifications- Other Name: Joint Kit, Propeller Shaft Universal Joint; U Joint

- Position: Front

- Replaces: 12471502, 12479126, 26042371

GMC Universal Joints Part Number: 94772179

$163.83 MSRP: $273.43You Save: $109.60 (41%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Kit-Front Axle Propeller Shaft Front Universal *Outside Snap; U Joint; Joint Kit, Propeller Shaft Universal Joint

- Position: Front

- Replaced by: 89059111

GMC Universal Joints Part Number: 89059111

$163.83 MSRP: $273.43You Save: $109.60 (41%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint Kit, Front Axle Propeller Shaft Universal *Outside Snap; Slip Yoke; Joint Kit, Propeller Shaft Universal Joint

- Position: Front

- Replaces: 12472409, 12476231, 12471503, 12522048, 26049843, 88982758, 88964507, 94772179, 12476230

GMC Universal Joints Part Number: 89040245

$107.41 MSRP: $180.82You Save: $73.41 (41%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint Kit, Propeller Shaft Rear Universal; U Joint; Joint Kit, Propeller Shaft Universal Joint

- Position: Rear

- Replaces: 12472402, 12543576, 15577432, 12476136

GMC Universal Joints Part Number: 89040243

$112.32 MSRP: $189.10You Save: $76.78 (41%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint Kit, Propeller Shaft Front Universal; U Joint; Joint Kit, Propeller Shaft Universal Joint

- Position: Front

- Replaces: 12543573, 12473124, 12476135

GMC Universal Joints Part Number: 88964413

$196.62 MSRP: $328.19You Save: $131.57 (41%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint Kit, Front Axle Propeller Shaft Universal *Outside Snap; U Joint; Joint Kit, Propeller Shaft Universal Joint

- Position: Front

- Replaces: 12385742, 12472406, 15599179, 19256729, 88982759, 12478057, 12471510, 12476310

GMC Universal Joints Part Number: 19256729

$196.62 MSRP: $328.19You Save: $131.57 (41%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint Kit, Propeller Shaft Universal (1415 Serie*Outside Snap; U Joint; Joint Kit, Propeller Shaft Universal Joint

- Replaced by: 88964413

GMC Universal Joints Part Number: 19121436

$130.13 MSRP: $308.44You Save: $178.31 (58%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint Kit, Propeller Shaft Universal; U Joint; Joint Kit, Propeller Shaft Universal Joint

- Replaces: 15515792, 19256890, 15898097, 88934794, 88935919

GMC Universal Joints Part Number: 84807275

$124.76 MSRP: $212.40You Save: $87.64 (42%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Joint Kit, Propeller Shaft Universal Joint; U-Joint

- Replaces: 23471515, 84712242

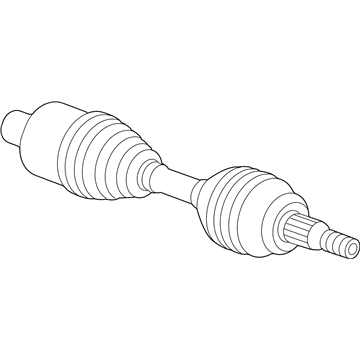

GMC Inner CV Joint Part Number: 84666185

$79.35 MSRP: $124.29You Save: $44.94 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Outer CV Joint; Joint Kit, Front Wheel Drive Axle; CV Joint

- Position: Inner

GMC Universal Joints Part Number: 84922957

$161.32 MSRP: $253.81You Save: $92.49 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Kit, Propeller Shaft Universal Joint; CV Joint; U Joint; U-Joint

- Replaces: 84272144

GMC Universal Joints Part Number: 84922956

$148.18 MSRP: $233.17You Save: $84.99 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Kit, Propeller Shaft Universal Joint; CV Joint; U Joint; U-Joint

- Replaces: 84272143

GMC Universal Joints Part Number: 84712242

$124.76 MSRP: $212.40You Save: $87.64 (42%)Ships in 1 Business DayProduct Specifications- Other Name: Joint Kit, Propeller Shaft Universal Joint; CV Joint; U Joint; U-Joint

- Replaced by: 84807275

GMC Universal Joints Part Number: 84679955

$46.47 MSRP: $72.79You Save: $26.32 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Kit, Propeller Shaft Universal Joint; CV Joint; U Joint; U-Joint

GMC Universal Joints Part Number: 84679948

$59.93 MSRP: $93.89You Save: $33.96 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Kit, Propeller Shaft Universal Joint; CV Joint; U Joint; U-Joint

GMC Universal Joints Part Number: 84555910

$46.37 MSRP: $72.63You Save: $26.26 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Kit, Propeller Shaft Universal Joint; CV Joint; U Joint; U-Joint

GMC Universal Joints, Rear Part Number: 84526285

$34.70 MSRP: $59.11You Save: $24.41 (42%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Joint Kit-Front Axle Propeller Shaft Rear Universal; U Joint; Joint Kit, Propeller Shaft Universal Joint

- Position: Rear

GMC Universal Joints Part Number: 89040339

Product Specifications- Other Name: Joint Kit, Front Axle Propeller Shaft Universal; U Joint; Joint Kit, Propeller Shaft Universal Joint

- Position: Front

GMC Universal Joints Part Number: 7849090

Product Specifications- Other Name: Joint Kit, Propeller Shaft Universal; U Joint

GMC Universal Joint

Want to cut long-term maintenance and repair costs? Choose OEM Universal Joint. Those parts deliver top durability you can trust. On our site, you'll find a huge catalog of genuine GMC parts. Prices are unbeatable, so you can keep more in your pocket. Every OEM GMC Universal Joint includes a manufacturer's warranty. You can also get an easy return policy that keeps buying risk free. Fast delivery, get your car on the road quickly. It's simple to search, compare, and order. Stop guessing about quality or fit. Order today and save with parts that last.

GMC Universal Joint Parts Questions & Experts Answers

- Q: How to Properly Service a Universal Joint with an External Snap Ring on GMC Canyon?A:To fix the universal joint start by preparing these tools U-Joint Bearing Separator model J 9522-3 and U-Joint Bearing Spacer Remover tool J 9522-5. Keep the propeller shaft in a horizontal position while supporting it and never fit the tubing in a vise because it damages the shaft. Label the shaft ends before taking out the snap rings with pliers. Lightly tapping on the cup will help the ring exit when it does not come out freely. Set the lower yoke support onto either a 30 mm (1-1/8 in) hex socket head or a 27 mm (1-1/16 in) socket tool. Then use the U-Joint Bearing Separator (J 9522-3) device to push the lower bearing cup out from the horizontal opening. Install the U-Joint Bearing Spacer Remover tool (J 9522-5) when the standard process to remove the bearing cup does not work. Use the propeller shaft rotation to push out the other bearing cup and temporarily note its position for correct reassembly. Look through the bores of the bearing cups and retaining ring grooves for debris then assess each area for irregularities in the surface. Insert one bearing cup into the yoke side then fit the cross over it before pushing the cup until it meets the surface of the yoke. Apply the second bearing cup to its proper location and press it into position while making sure the trunnions line up. After seeing a clear slot in the retainer groove you must press both bearing retainers into place before using a dead blow hammer when needed to fully seat the retainers. The snap ring installation is smoother with a coating of chassis grease for the operation.

- Q: How to replace the universal joint with a nylon injected ring on GMC Sierra 1500?A:You can set up and mark the yoke ends before putting the propeller shaft into a horizontal press with nylon support. Use a 30mm 1 1/8" socket in one yoke ear to support the propeller shaft when applying J 9522-3 bearing separator between horizontal bearing cups to push the lower bearing out. When the bearing cup proves stubborn, use the J 9522-5 to exceed pressure between the seal and cartrige by inserting it between the two surfaces. Turn the propeller shaft to drive the opposite bearing cup out and take off the cross assembly and joint parts separately. Use a clean tool to push away small plastic fragments inside the bearin. Lay one bearing cup inside the yoke then attach the yoke's bottom end piece. Afterward, put the cross parts together ensuring the trunnion moves without obstacles. Push both bearing cups into the yoke unit until the tips reach the surface then do the same on the other side to line up trunnion parts. Check the needle bearing alignment when a running problem exists. Press the yoke while ensuring the bearing retainer groove moves away then put the bearing retainer parts into place and tap them until both pieces snap into place. A dead blow hammer may be used to gently push the yoke when retainer installation becomes difficult. Adding chassis grease to the snap ring also helps ensure correct placement.

- Q: How to replace the universal joint with an external snap ring on GMC Yukon?A:To replace the Universal Joint with an external snap ring, first, you should lay the propeller shaft on the press table horizontally so as not to damage the tubing by clamping it in a vice. Tag the propeller shaft to show the transmission and rear axle connections. Disassemble using pliers the snap rings and, if needed, tap the cup end lightly to relieve pressure. Start the support of the lower ear of the yoke onto 30 mm (1-1/8 in) hex head socket or onto 27 mm (1-1/16 in) socket and then to place j 9522-3 onto the open horizontal bearing cups in order to press the lower bearing cup out of the yoke ear. If the bearing cup fails to come out all the way, raise the cross and place j 9522-5 in between the seal and bearing cup to keep pressing it out. Rotate the propeller shaft to drive out the opposite bearing cup and note the orientation of Slip Yoke to tube that one therefore needs for reassembling. Remove the cross & other universal junt event as well and in the case of changing the front Universal Joint, take off bearing cups found on the Slip Yoke as well. Check retaining ring groove and bearing cup bore for cleanliness and imperfections and cleaning where necessary. For assembly, take bearings cups off from the Universal Joint and have one of the bearings cups half assembled into the one end of the yoke while the yoke ear is pointing down. Place the cross on the ends of the trunnion such that the trunnion fits freely in the bearing cup and push the bearing cup into the yoke until its flush with the yoke. Mount one of the opposite bearing cups partially inside a yoke ear making sure that the trunnions are pointing straight into the bearing cups. Press the contrary bearing cup as you check for the free movement of trunnions; if there is binding, check the needle bearings for misalignment. Press further applying pressure, up until you see the bearing cup retainer groove, then install the bearing retainer into the groove and press everything until both retainers snap into place. If fitting the retainer becomes difficult than a firm hammer blow from the kind of dead hammer (which is intended for such blow on snap ring) can help, and a little of the chassis grease can help paint the grease on the snap ring to smooth the entry.

Related GMC Parts

Browse GMC Universal Joint by Models

Acadia Sierra 1500 Yukon Canyon Sierra 2500 HD Envoy Sonoma Typhoon C1500 Envoy XL Jimmy K1500 Safari Savana 2500 Savana 3500 Sierra 2500 Sierra 3500 Yukon XL C2500 C3500 G2500 K2500 K3500 Savana 1500 Yukon XL 1500 C1500 Suburban C2500 Suburban G1500 G3500 K1500 Suburban K2500 Suburban Sierra 1500 Classic Sierra 1500 HD Sierra 1500 HD Classic Sierra 1500 Limited Sierra 2500 HD Classic Sierra 3500 Classic Sierra 3500 HD V1500 V1500 Suburban V2500 V2500 Suburban V3500 Yukon XL 2500